top of page

AISC/NSBA Design Example 5 "Three-Span Continuous Horizontally Curved Composite Steel Tub-Girder Bridge" is a benchmark example which is regularly updated by the NSBA and extensively covers multiple limit states to be addressed during design, from constructibility, strength, serviceability and fatigue. It is available at:

https://www.aisc.org/globalassets/nsba/design-resources/steel-bridge-design-handbook/b956_sbdh_appendix5.pdf

The screenhots below, including the top flange principal and lateral bending stress diagrams, are directly taken from the mBrace3D deck placement analysis model of the design example in question. The AASHTO LRFD constructibility checks are also conducted directly within the software, by automatically computing the unbraced lengths from the bracing pattern and the deck pouring sequence.

This model is available by clicking this button:

Deflected shape at the end of Pour 3, assuming a 12-hour gap between successive pours.

Top flange principal and lateral bending stresses at the end of Pour 3:

The slight assymetry is due to the assymetry in the deck placement sequence.

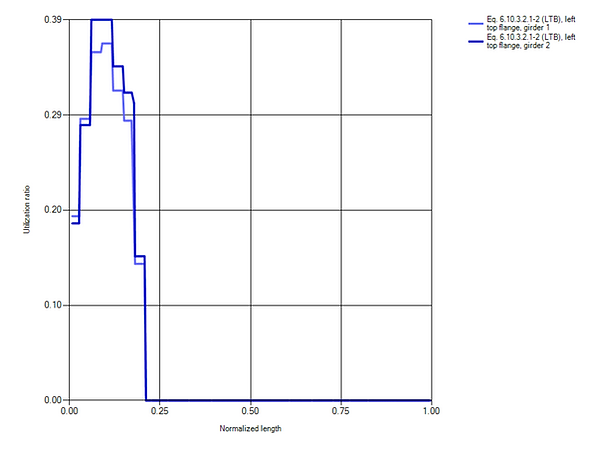

AASHTO LRFD Eq. 6.10.3.2.1-2 (LTB) constructibility check at the end of Pour 3:

Top flanges in the positive moment region of Span 1 are the only ones to which this check applies, as the other positive moment regions, previously poured during Pour 1 and Pour 2, are now acting compositely with the concrete deck and are not subjected to lateral-torsional buckling (LTB).

bottom of page